This my proposed design for our final, it doesnt concentrate too much on Barry's designs, but does include a basic transformer for output. Below is our final circuit. Which will most likely have to be modified as we have Yet to have any lab time.

Once again, please organise the labs better!

|

| Final Circuit |

Due to having limited board space since our product has to be handheld, and with our early casing designs being that of using a drill casing. I have decided to place the circuitry in the main body of the drill, allowing Barry to have the battery compartment for his transformer. I have decided to use the most possible space of the drill body by separating the circuit into 3 sections, or modules. In a similar way to that of my prototyping. Below show how the 3 layers will fit inside the body.

|

| Proposed design of stripboard inside casing |

My available workspace for the moment is 40x70mm for the top and bottom layers, and 50x70mm for the middle layer. The length of these boards could be increased to 90mm if the solenoid is placed elsewhere, however for the moment, I have mentally placed the solenoid just in front of the stripboard.

Keeping in line with my work process so far, the sections of stripboard will hold certain modules of the circuit. The bottom layer will contain the voltage regulator along with voltage indicators, this seems sensible because batteries, along with indicators will placed near the bottom of the device. The middle section will most likely hold the PIC along with components for the LCD display, Leaving the top board with the outputs for the gas and transformer, this is suitable as it can be reduced to allow wires for power and LCD to feed up through. With this in mind I will began to make initial Veroboard layouts.

Programmer:

To begin with a simple programming ciruit will have to be contructed for the PICAXE as it requires a 3.5mm stereo socket to be programmed. The circuit below will be contructed for two reasons, one being that the socket used is not breadboard friendly, so it will assist in prototyping. Also, since the chip will only be programmed once there is no need for it on our final design, so space is saved.

|

| Circuit of Programmer |

|

| Veroboard layout of programmer |

Parts List:

Part Quantity Cost (£) Total Cost(£)

3.5mm Headphone socket 1 0.08 0.08

3 pin header 1 0.009 0.009

10K Resistor 1

22K Resistor 1

Total cost 0.089

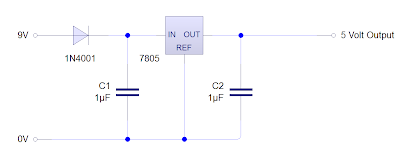

Power Section:

This layer consists of indicators for the the voltage along with a regulator to supply the PIC board with 5 volts. Feeds into this board are the battery and the main On/Off switch, the feeds off it, are the 18V, 5V and 0V rails.

|

| Circuit for Power layer |

|

| Veroboard layout (in black) of Power layer |

Parts List:

Part Quantity Cost (£) Total Cost(£)

SPST Switch 1 0.50 0.50

1N4001 Diode 1 0.024 0.024

7805 Voltage Regulator 1 0.17 0.17

Zener Diode 1 0.011 0.011

Green LED 1 0.036 0.036

Red LED 1 0.036 0.036

BC108 Transistor 2 0.193 0.386

PP3 Battery Snap 2 0.46 0.92

100µF Capacitor 2

10K Resistor 1

2.2K Resistor 2

820 Resistor 2

Total cost 2.083

1N4001 Diode 1 0.024 0.024

7805 Voltage Regulator 1 0.17 0.17

Zener Diode 1 0.011 0.011

Green LED 1 0.036 0.036

Red LED 1 0.036 0.036

BC108 Transistor 2 0.193 0.386

PP3 Battery Snap 2 0.46 0.92

100µF Capacitor 2

10K Resistor 1

2.2K Resistor 2

820 Resistor 2

Total cost 2.083

PIC Section:

For the middle layer, the PIC along with the LCD driver chip and the 3 main inputs to the device have been.

With this initial design, the board has reached its designed limit of 19x28 holes, which I have calculated form the dimensions in millimetres.

|

| Circuit of middle layer |

|

| Veroboard layout of main section |

PIC16F819 1 1.512 1.512

4MHz Resonator 1 0.08 0.08

PTM switch 3 0.247 0.741

8 Pin IC Socket 1 0.02 0.02

10K Resistor 3

1K Resistor 3

4.7K resistor 1

Total cost 4.052

Outputs Section:

This will be a the top and final layer of the overall circuitry. It will be a very simple board, but will help in its reduced size to allow wiring for the LCD module and other inputs to feed through. Also, if anything burns out, only one small board will be changed instead of the entire thing, which will keep cost and time to a minimum. The 18v rail will feed from the initial power board, and outputs for the solenoid, (which will control the gas) and the frequency for the transformer will be the outputs

|

| Circuit for Output Board |

Part Quantity Cost (£) Total Cost(£)

1N4001 Diode 1 0.024 0.024

Mosfet 2 0.38 0.76

10K Resistor 2

Total cost 0.784

Complete Parts List

Part Quantity Cost (£) Total Cost(£)

Programmer 1 0.089 0.089

Power Section 1 2.083 2.083

PIC Section 1 4.052 4.052

Outputs Section 1 0.784 0.784

LCD 8x2 Display 1 2.22 2.22

Solenoid 1 0.987 0.987

Total cost for circuit of project £10.215

As you see, this is our design proposal. Although prices for resistors and capacitors have been omitted from the final price, in addition to cost of wire and veroboard. We feel, even with those prices added we would still be under our initial £15 budget. With this, we have given ourselves a five pound allowance, in case any extra, or replacement components need to be ordered.

Complete Parts List

Part Quantity Cost (£) Total Cost(£)

Programmer 1 0.089 0.089

Power Section 1 2.083 2.083

PIC Section 1 4.052 4.052

Outputs Section 1 0.784 0.784

LCD 8x2 Display 1 2.22 2.22

Solenoid 1 0.987 0.987

Total cost for circuit of project £10.215

As you see, this is our design proposal. Although prices for resistors and capacitors have been omitted from the final price, in addition to cost of wire and veroboard. We feel, even with those prices added we would still be under our initial £15 budget. With this, we have given ourselves a five pound allowance, in case any extra, or replacement components need to be ordered.